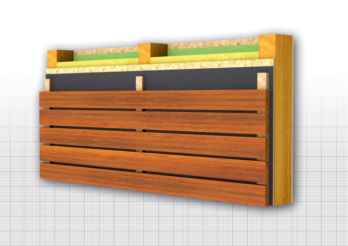

Façade membrane WÜTOP® insulated façade for wind and rainproof façade constructions

Facade sheet, WÜTOP Thermo Fassade

FCNGSHT-THERMO-2SK-L50M-W1,5M-75SM

Art.-no. 0681001060

EAN 4050382688125

Register now and access more than 10,000 products

- Windproof and rainproof

- Protects the insulation from pounding rain and blown snow

- Normally inflammable

- Highly vapour-permeable

- High UV resistance

- Joint portion of façade surface up to 40%

- Clear joint width up to 50 mm

- Quick and efficient application

- Black surface

- Processing temperature +5°C to +50°C

DIN EN 13859-2

- The applicable standards, technical regulations and application instructions must be observed during application.

- DIN 18516-1 and DIN 1055 parts 1-4 must be adhered to during installation

DIN EN 13859-2

Datasheets(X)

WÜTOP Thermo Façade is suitable for all back-ventilated façade structures with joints up to 5 cm wide. The joint portion of the façade may not exceed 40% in total.

WÜTOP Thermo Façade is the optimum solution for creating a wind and rainproof façade construction that is diffusion-open on wooden stand structures, metal constructions and renovations. it provides an excellent living climate thanks to its outstanding physical construction properties. WÜTOP air and vapour barriers/vapour seals are best suited to protect heat insulation from the inside.

In case of different installation requirements, it is imperative that you consult us. Align the membrane horizontally or vertically to the foundation on the substructure with the coated side outwards and secure it in the overlapping area. Starting on one side, fix the membrane into its final position on the substructure in the overlapping area, keeping the membrane under constant tension (using a hammer tacker, art. no. 0714854 or 0714811 or manual stapler art. no. 0714834). Install subsequent membranes under tension as described above with at least 10 cm overlap. Ensure fastenings are covered. Then seal overlaps using adhesive tape under constant pressure and without wrinkles. Ensure that no points bonded using EURASOL Max are located in the open joint portion (not permanently UV resistant). In this case, please do not use the self-adhesive version. Fastenings outside the overlapping area must be sealed and windproof (using EURASOL Max adhesive tape, art. no. 0992710160, 0992710161). Openings, connections and edges must be made permanently airtight and vapour-tight using adhesive materials suitable for outdoor use (e.g. WÜTOP WRD adhesive, art. no. 0893700115), and must be secured using a clamping batten or clip. Any damage to the WÜTOP Thermo Façade membrane must be repaired using patches of original membrane and suitable adhesive tape (EURASOL Max, art. no. 0992710160, 0992710161). Processing temperatures from +5°C to +50°C must be observed. DIN 18516-1 and DIN 1055 parts 1-4 must be observed during installation. Cladding must be installed no later than 3 months after installing the WÜTOP Thermo Façade membrane. However, we recommend fitting the façade cladding quickly.

Design | With self-adhesive strips |

Coating weight per m² | 220 g |

Length of roll | 50 m |

Roll width | 1.5 m |

Area | 75 m² |

Number of rolls per pallet | 20 PCS |

Material | Polyester fleece |

Thickness | 0.5 mm |

Suitable for makeshift roofing/makeshift coverage | 4 Weeks |

Ultraviolet resistance | 3 months outdoor weathering/yes with clear joint width up to 50 mm |

Min./max. temperature resistance | -30 to 80 °C |

Colour | Black |

Building material class/conditions | E - Normally inflammable / in accordance with DIN EN 13501 |

Air layer thickness equivalent to water-vapour diffusion/conditions | 0.1 m / in accordance with DIN EN 12572 C |

Resistance to penetration of water | W1 |

Resistance to tear propagation (longitudinal) | 200 N |

Resistance to tear propagation (transverse) | 200 N |

Longitudinal tensile force per 50 mm | 265 N |

Transverse tensile force per 50 mm | 315 N |

Stretch capacity/conditions | 55 % / in accordance with DIN EN 12311-1 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!